About Course

https://youtu.be/69OXymlelyY

Fundamentals of Surface Engineering: Mechanisms, Processes, and Characterizations.

The course content is designed to have a systematic and comprehensive understanding of various aspects related to surface engineering of metallic components for enhanced tribological life.

It is proposed to include fundamental mechanisms of wear such as adhesive, abrasive, erosive, cavitation, corrosion, etc., governing laws, materials properties importance for improved wear resistance under different wear conditions, materials increased tribological life, processes for engineering surfaces of three board categories a) regulating the micro-structure without changing chemical composition b) modification of the chemical composition of near-surface layers and c) developing of films, coating, and cladding on the.

Methods of the characterization needed for evaluating the metallurgical and mechanical and tribological properties and performance of engineered surfaces shall also be presented. Presentations will be supported with case studies for effective communication of concepts and procedures. Case studies will be taken up regarding surface engineering of various metal systems like ferrous and non-ferrous metals using different approaches discussed.

Fundamentals of Surface Engineering INTENDED AUDIENCE: UG and PG Student, Research Scholar & Practicing Engineers

Course Content

Fundamentals of Surface Engineering: Mechanisms,Processes and Characterizations

-

Fundamentals of Surface Engineering Mechanisms,Processes and Characterizations

00:00 -

Introduction and need of surface engineering

00:00 -

Surface/sub-surface regions and properties of importance for surface engineering

00:00 -

Surface properties and their modification

00:00 -

Classification of surface modification techniques I

00:00 -

Classification of surface modification techniques II

00:00 -

Scope of surface engineering I

00:00 -

Comparison of surface modification techniques and scope of surface engineering

00:00 -

Surface properties for wear and friction resistance I

00:00 -

Surface properties for wear and friction resistance II

00:00 -

Surface properties for wear and friction resistance III

00:00 -

Issues and application of surface modification

00:00 -

Surface damage: type and categories

00:00 -

Surface damage: Adhesive wear I

00:00 -

Surface damage: Adhesive wear II

00:00 -

Surface damage: Classical law of adhesive wear and abrasive wear

00:00 -

Properties and mode of wear

00:00 -

Thermal barrier coatings

00:00 -

Functionally graded materials and other materials

00:00 -

Surface modification techniques: Principle of controlling surface metallurgy

00:00 -

Surface modification techniques: Controlling surface metallurgy I

00:00 -

Surface modification techniques: Controlling surface metallurgy II

00:00 -

Surface modification techniques: Controlling surface metallurgy III

00:00 -

Surface modification techniques: Controlling surface metallurgy IV

00:00 -

Surface modification techniques: Changing surface composition

00:00 -

Surface modification techniques: Carburizing I

00:00 -

Surface modification techniques: Carburizing II

00:00 -

Surface modification techniques: Nitriding

00:00 -

Surface modification techniques: Vacuum based surface modification I

00:00 -

Surface modification techniques: Ion implantation and ion plating

00:00 -

Surface modification techniques: Sputtering and Ion beam assisted deposition

00:00 -

Surface modification techniques: Chemical vapour deposition and boronizing

00:00 -

Surface modification techniques: Laser alloying

00:00 -

Surface modification techniques: Carburizing and Cyaniding

00:00 -

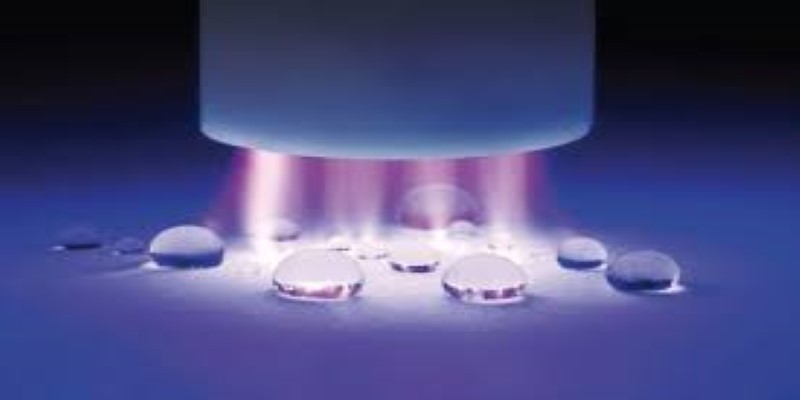

Surface modification techniques: Plasma carburizing & plasma nitriding

00:00 -

Surface damage: Abrasive wear I

00:00 -

Surface damage: Abrasive wear II

00:00 -

Surface damage: Erosive wear

00:00 -

Surface damage: Melting wear and corrosive wear

00:00 -

Surface modification techniques: Laser nitriding and developing surface layer

00:00 -

Surface modification techniques: Fundamentals of surface modification by weld surfacing and thermal

00:00 -

Surface modification techniques: Fundamentals of surface modification by weld surfacing

00:00 -

Surface modification techniques: Weld surfacing processes

00:00 -

Surface modification techniques: Weld surfacing I

00:00 -

Surface damage: Diffusive wear and evaluation of surface damage

00:00 -

Metal systems

00:00 -

mod10lec46

00:00 -

mod10lec47

00:00 -

mod10lec48

00:00 -

mod10lec49

00:00 -

mod10lec50

00:00 -

mod11lec51

00:00 -

mod11lec52

00:00 -

mod11lec53

00:00 -

mod11lec54

00:00 -

mod11lec55

00:00 -

mod12lec56

00:00 -

mod12lec57

00:00 -

mod12lec58

00:00 -

mod12lec59

00:00 -

mod12lec60

00:00

Student Ratings & Reviews