About Course

Welding of Advanced High Strength Steels for Automotive Applications.

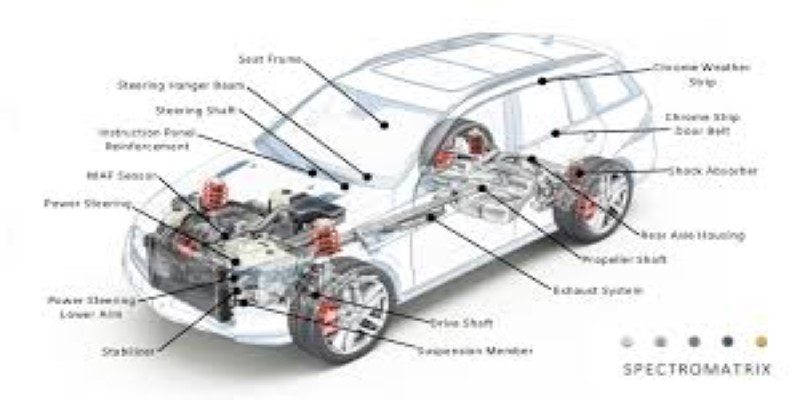

The use of advanced high strength steels (AHSS) is increasingly preferred in automotive applications due to improved crash energy management and enhanced strength-ductility combinations, resulting in greener and safer vehicles. The weldability of AHSS is generally poorer than conventional steels due to the high alloying contents required to obtain a multi-phase microstructure. This course is aimed to discuss the (i) role of alloying elements in stabilizing multi-phase microstructures of AHSS, (ii) the effect of weld thermal cycles on the evolution of microstructures, and (iii) weldability of AHSS.

INTENDED AUDIENCE: Final year bachelor’s and master’s students in Metallurgy, Mechanical, Automobile, and Production Engineering. Industrial personnel working in automotive and steel-making industries.

Course Content

Welding of Advanced High Strength Steels for Automotive Applications

-

Introduction to the course, Introduction to physical metallurgy of steels

00:00 -

Quantification of Microstructural Constituents in Automotive Steel Welds Part – II and Mechanical Pr

00:00 -

Quantification of Microstructural Constituents in Automotive Steel Welds Part – I

00:00 -

Elemental Behaviour During Welding of Advanced High Strength Steels

00:00 -

Microstructural Evolution During Welding of Advanced High Strength Steels

00:00 -

Welding Metallurgy of Advanced High Strength Steels – Part – I

00:00 -

Principles of Gas Metal Arc Welding – Part – I

00:00 -

Principles of Gas Metal Arc Welding – Part – II

00:00 -

Introduction to Laser Beam Welding – Part – I

00:00 -

Methodologies to Improve the Weldability of Advanced High Strength Steels

00:00 -

Thermal and Mechanical Processing of TRIP and Hot Forming Steels

00:00 -

Martensitic transformation, Introduction to modern automotive steels

00:00 -

Introduction to modern automotive steels

00:00 -

Introduction to advanced high strength steels

00:00 -

Introduction to Dual Phase Steel and TRIP Steel Heat Treatments

00:00 -

Process Characteristics of Resistance Spot Welding – Part – I

00:00 -

Process Characteristics of Resistance Spot Welding – Part – II

00:00 -

Principles of Resistance Spot Welding (RSW)

00:00 -

Introduction to Welding Processes in Automotive Industries

00:00 -

Introduction to Laser Beam Welding – Part – II

00:00

Student Ratings & Reviews

No Review Yet