About Course

Basic Mechanical Engineering part 2

Mechanical engineering is a broad field that encompasses the design and development of various machines, tools, and systems. It is one of the oldest and broadest engineering disciplines, and it is responsible for the design, manufacture, and operation of machines, systems, and tools. Mechanical engineering involves the application of physical principles to the design and operation of machines and systems. These principles include thermodynamics, mechanics, materials science, and electrical engineering. Mechanical engineers are responsible for the design and development of various types of machines, such as engines, pumps, compressors, turbines, generators, and motors. They also design and develop tools and systems for automation, such as robotic systems, computer-aided design (CAD) software, and computer-aided manufacturing (CAM) systems. Additionally, mechanical engineers design and construct power plants, engines, and other energy-conversion systems. In order to achieve the desired results, mechanical engineers must be proficient in mathematics, physics, and engineering. They must also possess strong problem-solving and analytical skills. Mechanical engineers are responsible for the design, testing, and operation of various types of machines and systems. They analyze the system’s components to determine the best configuration for optimal performance. They must also ensure that the machines and systems are safe and efficient. In order to ensure that machines and systems are reliable, mechanical engineers must conduct tests to measure the performance of the components. They must also troubleshoot and repair any problems that arise during operation. Mechanical engineers must also be aware of the environmental and safety regulations that apply to the operation of machines and systems. They must ensure that the machines and systems comply with these regulations. In addition to designing and operating machines, mechanical engineers are responsible for the maintenance and repair of various types of machines and systems. They must inspect and troubleshoot components to identify any potential problems. Mechanical engineering is a highly versatile field. It can be applied to a wide range of industries, from automotive to aerospace. Mechanical engineers are also involved in the development of new technologies, such as renewable energy systems, robotics, and sustainable materials. Mechanical engineering is a challenging and rewarding profession. It requires a great deal of creativity, problem-solving ability, and technical knowledge. Mechanical engineers are essential to the advancement of technology and the improvement of quality of life.

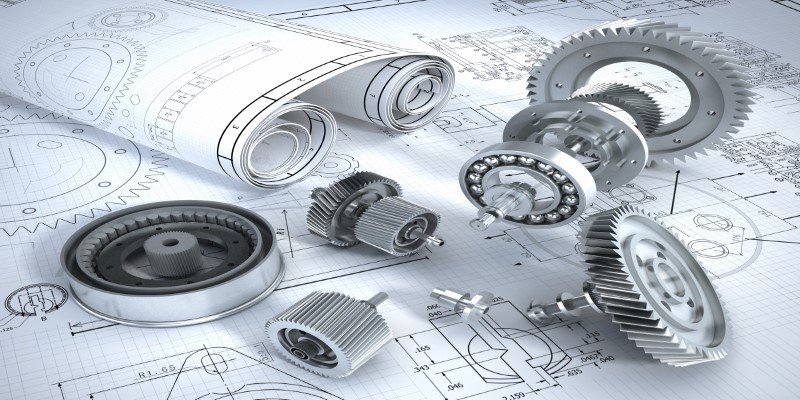

This course is a basic introductory course for all those who wish to learn technical concepts of Mechanical Engineering. Simple animations and basic definitions will enhance your learning experience. Simple concepts and different basic systems of mechanical engineering will be covered here. Animations and diagrams will increase your interests while learning. Basic systems in Automobile, Shafts, Bearings, Gears, etc. will be covered to give a realistic application-based feel of Mechanical Engineering.

Who this course is for:

- Anyone Who wants to Learn Engineering concepts. School As well As Engineering Students.

- Beginner Level for Mechanical Engineering.

Course Content

Basic Mechanical Engineering part 2

-

Non flow process, Types of process, Thermodynamic process, Important formula for process, BME

06:59 -

Adiabatic equation,Adiabatic process,Adiabatic governing equation,Derivation of adiabatic Equation

07:31 -

Adiabatic process, Isentropic process, Work done during Adiabatic process, Enthalpy change, BME

07:06 -

Polytropic process / Special cases of Polytropic process / Thermodynamic processes on pV diagram

06:37 -

Heat engine, Requirements of heat engine, Characteristics of heat engine, Efficiency of Heat Engine

03:41 -

Classification of heat engine, Heat engine parts, Components of heat engine, Heat engine diagram

06:10 -

Carnot cycle, Efficiency of Carnot cycle, Derivation of Carnot efficiency, Animation of Carnot cycle

10:44 -

Assumptions of Carnot cycle, Limitations of Carnot cycle, Carnot Limitations, Carnot Assumptions

00:00 -

Rankine cycle, Efficiency of Rankine cycle, pv and Ts diagram of Rankine cycle, Work done in Rankine

00:00 -

Air standard cycle, Air standard Efficiency, Assumptions of Air standard cycle, Importance of cycle

00:00 -

Otto cycle, Efficiency of Otto cycle, Derivation for Efficiency of Otto cycle, Otto cycle Efficiency

00:00 -

Examples on Otto cycle, 1 , Numericals on Otto cycle, BME, Problems on Otto cycle, OTTO Cycle

00:00 -

Examples on Otto cycle, 2 , Numericals on Otto cycle, BME, Problems on Otto cycle, OTTO Cycle

00:00 -

Examples on Otto cycle, 3 , Numericals on Otto cycle, BME, Problems on Otto cycle, OTTO Cycle

00:00 -

Diesel cycle, Diesel cycle Efficiency, Constant pressure cycle, Efficiency of Diesel cycle, BME

00:00 -

Example on Diesel cycle, 1, Diesel cycle, Diesel cycle problems, Numericals on Diesel cycle, BME

00:00 -

Example on Diesel cycle, 2, Diesel cycle, Diesel cycle problems, Numericals on Diesel cycle, BMEsson

00:00 -

Example on Diesel cycle, 3, Diesel cycle, Diesel cycle problems, Numericals on Diesel cycle, BME

00:00 -

IC engine parts, Components of IC engine, Main parts of IC Engine, IC Engine, Elements of IC Engine

00:00 -

IC engine terms, Important Terms of IC engine, Terminology used in IC engine, TDC, BDC, BME

00:00 -

IC engine performance parameters, Brake thermal efficiency, Indicated thermal efficiency, BSFC, BME

00:00 -

Classification of IC Engine, Types of IC Engine with Animation, IC engine types, BME

00:00 -

Four stroke petrol Engine, Working of petrol engine, How 4 stroke engine works, Animation of engine

00:00 -

How to draw four stroke petrol engine?, Four stroke petrol engine, 4 stroke engine, IC Engine, BME

00:00 -

Difference between Four stroke and Two stroke Engine, Two Stroke Engine, Four Stroke Engine

00:00 -

Difference between Petrol and Diesel engine, Difference between SI and CI engine, IC engine, BME

00:00 -

Centrifugal pump, Animation of Centrifugal pump, Water pump, Working of Centrifugal pump, BME

00:00 -

Centrifugal Pump, Animation of Centrifugal Pump, Block Diagram of Centrifugal Pump, Pump

00:00 -

Reciprocating pump, Animation of Reciprocating pump, Block diagram of Reciprocating pump, Water pump

00:00 -

Difference between Reciprocating & Centrifugal pump, Comparison of Centrifugal & Reciprocating pump

00:00 -

How to draw Reciprocating pump, Reciprocating pump, Simple figure of Reciprocating pump, BME

00:00 -

Animation of Reciprocating pump, Reciprocating pump diagram, Reciprocating pump, Pump, Water pump

00:00 -

Air Compressor, Reciprocating Air Compressor, Application of compressed air, Animation of Compressor

00:00 -

Classification of Air Compressor, Types of Air Compressors, Air Compressor types with Animation, BME

00:00