About Course

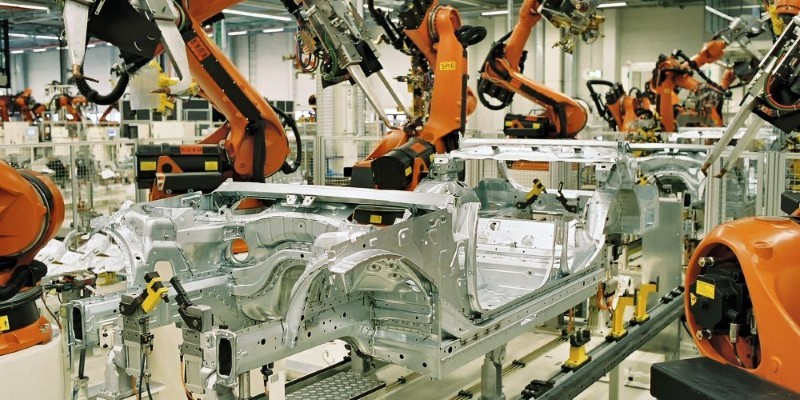

Automation in Manufacturing.

The manufacturing industry contributes a major share in the GDP of our country. The application of automated systems is certainly improving the productivity of the manufacturing industry.

In view of this, a course on “Automation in Manufacturing” is designed with the primary focus on the design and development of automated systems in manufacturing. Initially, the course introduces various automated systems being used in the manufacturing industry.

Then the building blocks of a typical automated system are described. It presents a study on the principle of operation and construction details of sensors/transducers, actuators, drives and mechanisms, hydraulic and pneumatic systems.

It also covers up the microprocessor technology, programming, and CNC technology. The contents are lucidly presented with real-life examples. Case studies based on manufacturing industry applications are presented.

INTENDED AUDIENCE: UG, PG students of Mechanical, Production, Industrial Engineering, Mechatronics Engineering. Practicing engineers.

Course Content

Automation in Manufacturing

-

Automation in Manufacturing [Intro Video]

00:00 -

Lec 21 Stepper motor and servo motor

00:00 -

Lec 22: Types of industrial automation and mechanisms

00:00 -

Lec 23: Ball screw based linear motion drives

00:00 -

Lec 25: Application of indexing mechanisms in automation

00:00 -

Lec 24: Application of cams in automation

00:00 -

Lec 26: Application of tool magazines in automation

00:00 -

Lec 27: Material handling systems

00:00 -

Lec 28: Fundamental concepts

00:00 -

Lec 29: Hydraulic pumps

00:00 -

Lec 30: Direction control valves

00:00 -

Lec 31: Flow control and pressure relief valves

00:00 -

Lec 32: Graphical representation of hydraulic system elements

00:00 -

Lec 33: Basic concepts and air compressors

00:00 -

Lec 34: Air treatment and pressure regulation

00:00 -

Lec 35: Graphical representation and pneumatic circuits

00:00 -

Lec 36: Computer aided manufacturing and process planning

00:00 -

Lec 37: CNC machines and interpolation

00:00 -

Lec 20: DC and AC motors

00:00 -

Lec 19: Application of electric drives in automation

00:00 -

Lec 18: Introduction to Microprocessor Programming

00:00 -

Lec 1: Basic concepts

00:00 -

Lec 2: Mechatronics

00:00 -

Lec 3: Mechatronics based systems

00:00 -

Lec 4: Automated systems and equipment used in manufacturing part-I

00:00 -

Lec 5: Automated systems and equipment used in manufacturing part-II

00:00 -

Lec 6: Selection of electrical and electronics components for mechatronics based systems

00:00 -

Lec 7: Terms related to performance of electro-mechanical systems

00:00 -

Lec 8: Computer aided design of components

00:00 -

Lec 9: Fabrication Processes

00:00 -

Lec 10: Measurement system and potentiometer sensors

00:00 -

Lec 11: Displacement, position and proximity sensors – I

00:00 -

Lec 12: Displacement, position and proximity sensors – II

00:00 -

Lec 13: Fluid flow, pressure, and temperature measurement

00:00 -

Lec 14: Signal Conditioning : amplification, filtering

00:00 -

Lec 15: Pulse modulation, Protection devices, and Wheatstone bridge

00:00 -

Lec 16: Signal conversion

00:00 -

Lec 17: Microprocessor Technology

00:00 -

Lec 38: CNC programming

00:00

Student Ratings & Reviews